Partial Stroke Devices

We are finding that safety is an ever more prominent feature in industry, process and day to day life. This safety focus is justified, not only to reduce the number of dangerous incidents that occur, but also tackle the causes of such incidents.

We are finding that safety is an ever more prominent feature in industry, process and day to day life. This safety focus is justified, not only to reduce the number of dangerous incidents that occur, but also tackle the causes of such incidents.

Wherever there is an Emergency Shutdown Valve (ESD) in a process, then there is a need for partial stroke testing. Not only could installing Partial Stroking Devices (PSD) ensure that you comply with important safety standards, but it could also save money!

One commitment that must be made when a plant incorporates an ESD valve is to visually inspect such a valve on a periodic basis. Basically the ESD valve must be tested to ensure that in an emergency, it will indeed shutdown. This is required in order to comply with 16.3.2 of ANSI/ISA-84.00.01-2004 Part 1.

No need for plant shutdown

Often ESD valves are situated on critical processes where there is a high revenue stream or increased risk due to the nature of the process itself or the medium being transported. On such applications, plant managers are faced with a real dilemma – to plan a shut down in order to fully stroke test the ESD valve can cost a huge amount in lost revenue stream.

However, instead of being faced with plant shutdown and potential loss of revenue, utilise Partial Stroking. It has been agreed that once a valve has travelled 20º of its stroke, then this is enough to demonstrate that the valve has not stuck and that the actuator is capable of fully closing the valve. So this is what we do, by utilising a mechanical partial stroking device developed by Dynatorque in the USA, named the D-Stop, we are able to allow the actuator to operate, but prevent it from travelling more than 20º of its stroke.

This effectively allows demonstration that the ESD system is operating as required, as well as maintaining sufficient flow in the pipeline not to disrupt revenue stream.

Increase the Safety Integrity Level

Another advantage of the D-Stop is that by using such a device, any plant can increase its Safety Integrity Level or SIL rating, which is of high importance to plants that utilise harmful materials and substances.

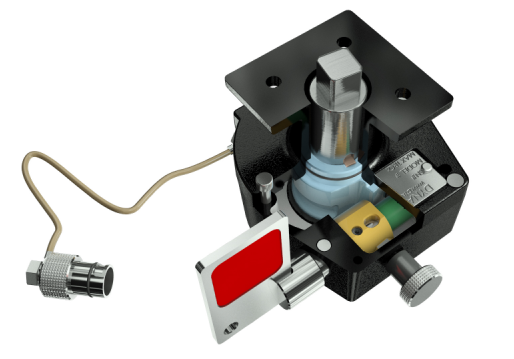

Mechanical Partial Stroke Testing Device, the D-Stop

The D-Stop is a purely mechanical device that incorporates a drive, housing, central quadrant and drive cam in order to physically stop the valve from travelling past a desired point in it’s stroke.